ʻO ka pauka hoʻoheheʻe ʻana i ka pāpaʻi plasma

Hōʻike huahana

ʻO nā waiwai maikaʻi loa o ka pauka alloy cobalt-based ma muli o kāna hana kemika kūikawā a me ka microstructure.Hana ʻia ia me nā ʻano metala like ʻole i hui ʻia e like me kekahi ʻāpana ma hope o ka hoʻoheheʻe ʻana o ka wela kiʻekiʻe, ʻoi aku ka kiʻekiʻe o ka ʻike o ka cobalt, no laila he paʻakikī maikaʻi a me ke kūpaʻa corrosion.I ka manawa like, loaʻa i ka alloy ka nui kūpono o ka hao, chromium a me nā mea ʻē aʻe, i ʻoi aku ka maikaʻi o ka pale ʻana.I ke kaʻina hana, hana ʻia ka pauka alloy cobalt me ka hoʻohana ʻana i kahi kaʻina hana metallurgy pauka.ʻO ka mea mua, ua hui pū ʻia nā mea metala e like me kekahi ʻāpana, a laila ma o ka hoʻoheheʻe ʻana i ka wela kiʻekiʻe, ka hoʻoheheʻe wikiwiki ʻana a me nā kaʻina hana ʻē aʻe, a loaʻa i ka pauka alloy maikaʻi.He kiʻekiʻe kiʻekiʻe o kēia pauka, hoʻopiha a me nā waiwai sintering, a hiki ke hana ʻia i loko o nā ʻano paʻakikī o nā ʻāpana.

Hōʻike

| 'ikamu | HR-Co1 | HR-Co6 | HR-Co12 | HR-Co21 |

| HRC | 48 | 38 | 42 | 28 |

| C | 2.4 | 1.15 | 1.4 | 0.25 |

| Cr | 30.5 | 29 | 29.5 | 27.5 |

| Si | 1 | 1.1 | 1.45 | 2 |

| W | 12.5 | 4 | 8.25 | 0.15 |

| Fe | 3 | 3 | 3 | 2 |

| Mo | 1 | 1 | 1 | 5.5 |

| Ni | 3 | 3 | 3 | 2.5 |

| Co | ʻO Bal | ʻO Bal | ʻO Bal | ʻO Bal |

| Mn | 0.25 | 0.5 | 1 | 1 |

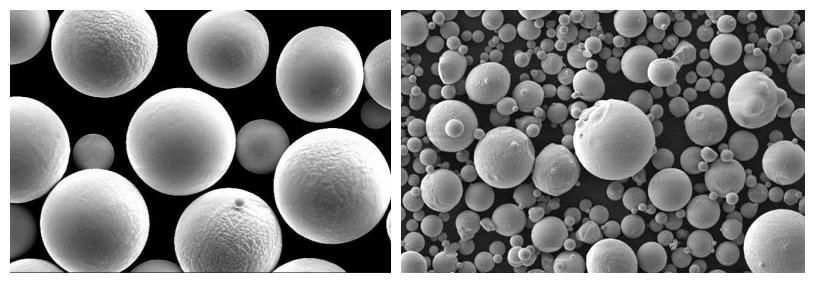

Ua haʻi aku ʻo Sem

Nā noi nui

He ikaika kiʻekiʻe ko Cobalt-based alloys, kūpaʻa maikaʻi i ka luhi wela, ka wela wela a me ka abrasion, a me ka weldability maikaʻi i nā mahana ma luna o 980 ℃.He kūpono no ka ʻenekini mokulele mokulele, ʻenekini kinoea ʻenehana, moku alakaʻi turbine alakaʻi vane a me ka nozzle alakaʻi vane a me ka nozzle diesel etc.

1. Paʻakikī

2.Wear-kū'āwili welding TIG/MIG

3. Thermal spray PTA/HVOF

HUARUI kobalt alloy pauda pono

● sphericity kiʻekiʻe

● kiʻekiʻe kemika haku mele homogeneity

● ʻike kiʻekiʻe / paʻi kiʻekiʻe

● Haʻahaʻa inclusions maʻiʻo

● Haʻahaʻa oxygen maʻiʻo

● High flowability

● Ka mānoanoa o ka ili like a me ka porosity haʻahaʻa