Paʻi 3D Nickel Based Alloy Inconel 718 Pauka

Hōʻike huahana

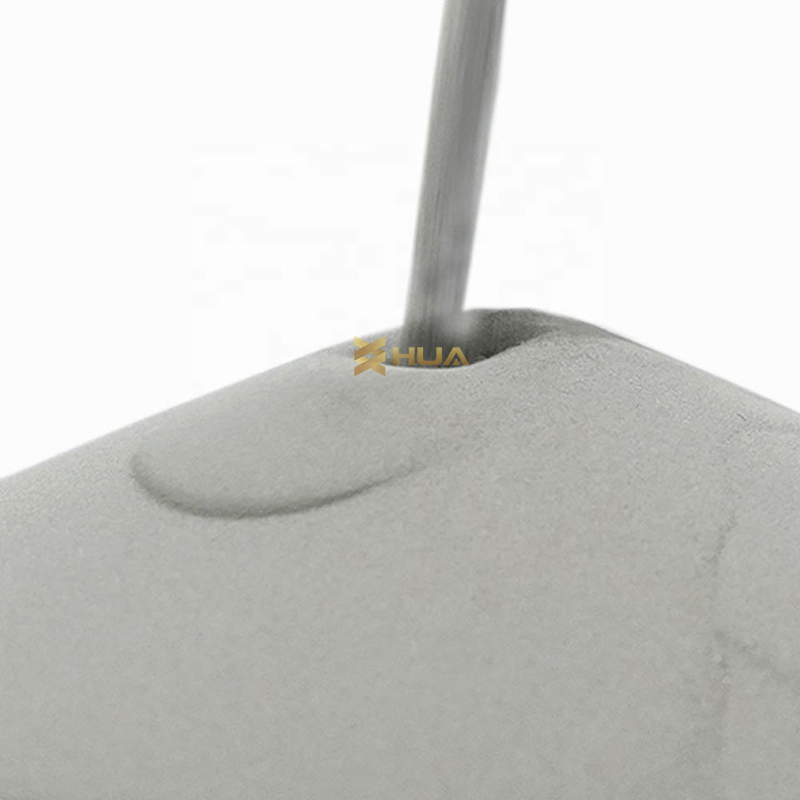

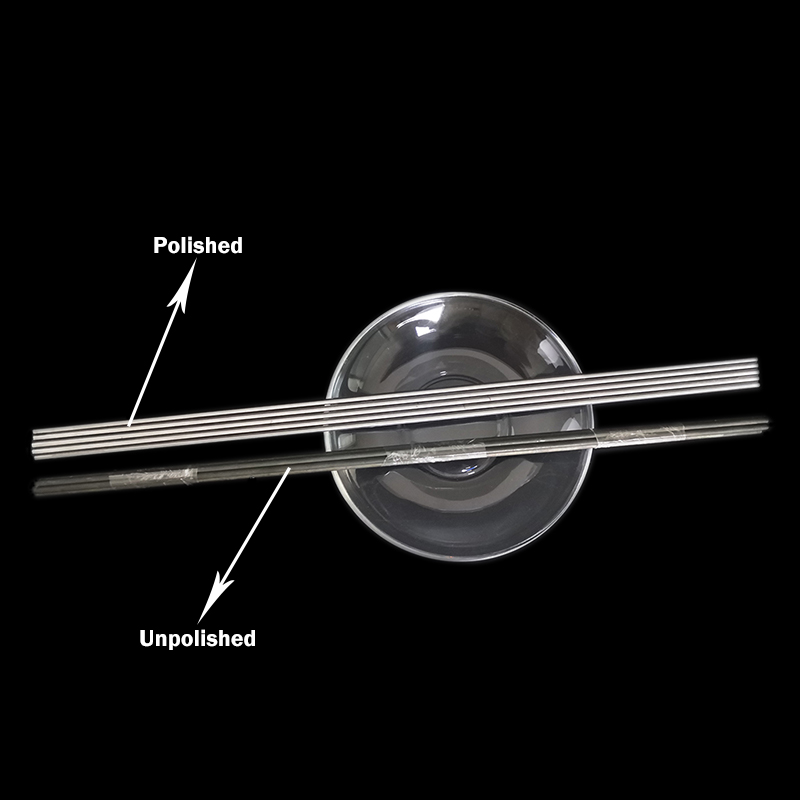

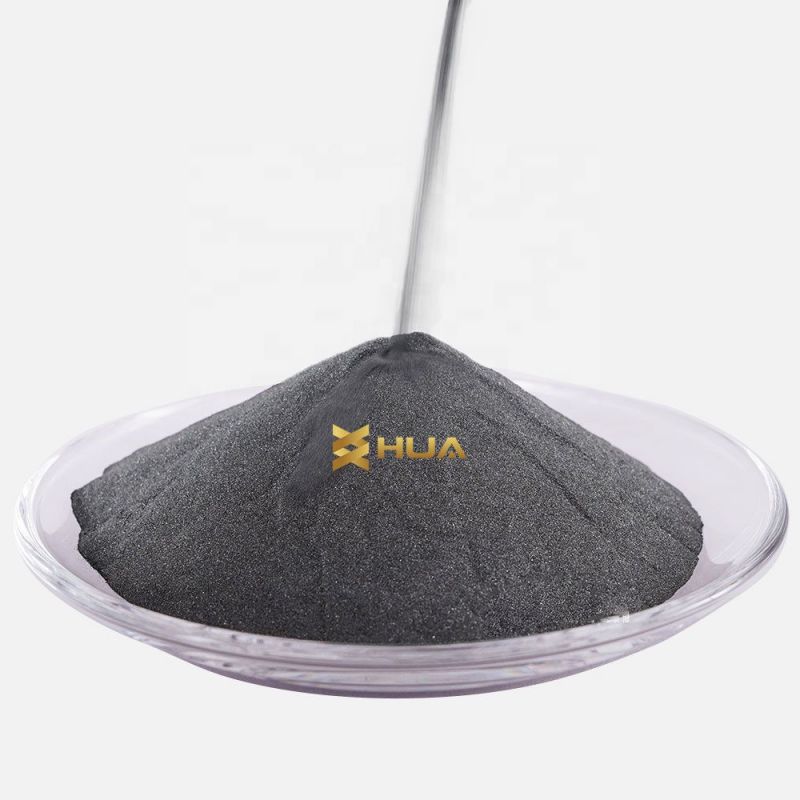

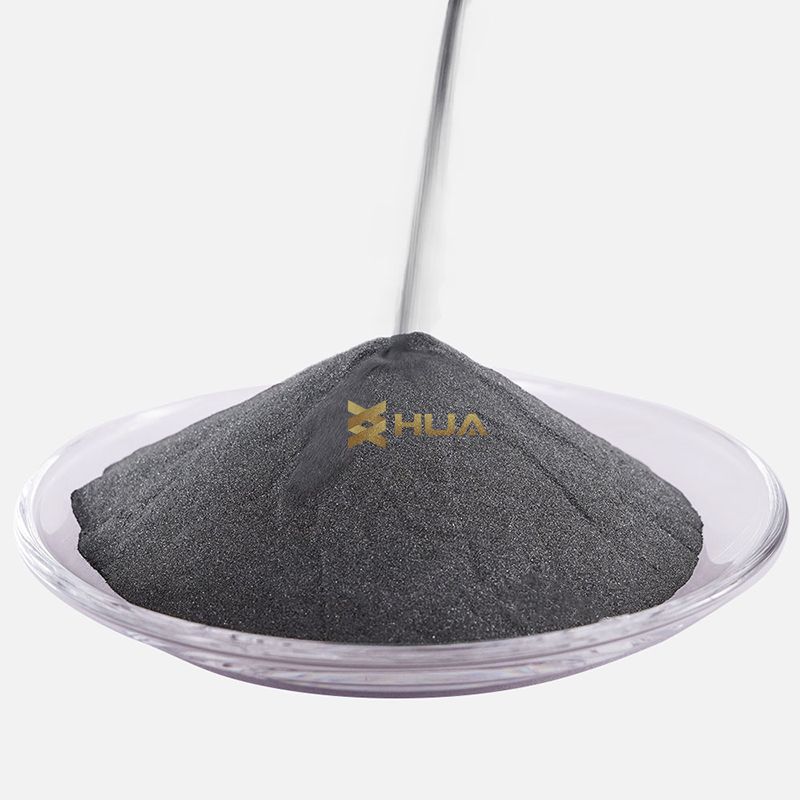

ʻO ka Inconel 718 pauka he sphericity maikaʻi, fluidity, wahi hoʻoheheʻe haʻahaʻa, kiʻekiʻe kiʻekiʻe o ka pale ʻana i ka oxidation, ka pale ʻana a me ka pale ʻana.Ma o ka mahele like ʻole o ka nui o nā ʻāpana.Hiki ke hoʻokaʻawale ʻia ka pauka nickel based alloy 718 i loko o ka pauka hoʻoheheʻe ʻia, ka pauka hoʻopaʻa ʻana i ka laser, ka pauka hoʻoheheʻe ʻana, ka pauka isostatic kaomi wela a pēlā aku.

Hōʻike

| Ka Hoʻohui Kemika(%) o Inconel 718 Pauka | |||||||

| C | Mn | Si | P | S | Cr | Co | Mo |

| ≤0.08 | ≤0.35 | ≤0.35 | ≤0.015 | ≤0.015 | 17-21 | ≤1.0 | 2.8-3.3 |

| Nb+Ta | Ti | Al | Fe | Cu | Ni | N | |

| 4.75-5.5 | 0.65-1.15 | 0.2-0.8 | ʻO Bal | ≤0.03 | 50-55 | ≤0.006 | |

| ʻO Inconel 718 Pauda Pono | |||||

| Lahi Nui | 0~25um | 0~45um | 15~45um | 45~105um | 75~180um |

| Morphology | Pōpoʻo | Pōpoʻo | Pōpoʻo | Pōpoʻo | Pōpoʻo |

| PSD (Mahele ʻĀpana ʻāpana) | D10: 6um | D10: 9um | D10: 14um | D10: 53um | D10: 78um |

| D50:16um | D50: 28um | D50: 35um | D50: 69um | D50: 120um | |

| D90: 23um | D90: 39um | D90: 45um | D90: 95um | D90: 165um | |

| Hiki ke kahe | N/A | ≤30S | ≤28S | ≤16S | ≤18S |

| ʻIke ʻia ʻo Density | 4.2g/cm3 | 4.5g/cm3 | 4.4g/cm3 | 4.5g/cm3 | 4.4g/cm3 |

| Maʻiʻo Oxygen (wt%) | O: 0.06~0.018wt% , maʻamau ASTM: ≤0.02 wt% | ||||

| 3D paʻi Gas Atomized Inconel 718 Pauka me ke kumu kūʻai maikaʻi loa | |||||

| (oxygen haʻahaʻa, sphericity kiʻekiʻe a me ka flowability maikaʻi) | |||||

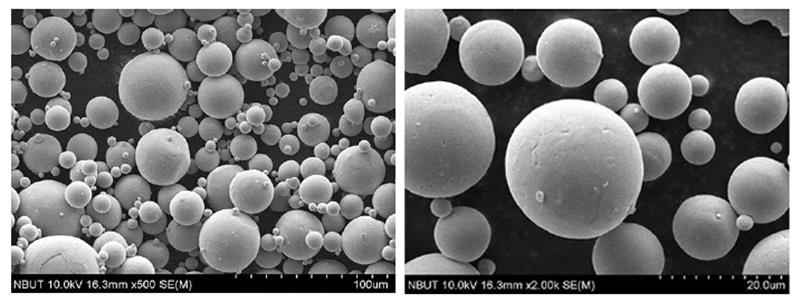

SEM

Palapala noi

1. HVOF

2. Hoʻopili plasma

3. Paʻi 3D

4. wili pauda

5. hoʻoheheʻe metala

6. isostatic wela

Pūnaehana hoʻomalu maikaʻi

He ʻōnaehana koʻikoʻi ko Huarui.Ho'āʻo mua mākou i kā mākou huahana ma hope o ka hoʻopau ʻana i kā mākou hana, a hoʻāʻo hou mākou ma mua o kēlā me kēia lawe ʻana, ʻo ia hoʻi ka laʻana.A inā makemake ʻoe, makemake mākou e ʻae i ka ʻaoʻao ʻekolu e hoʻāʻo.ʻOiaʻiʻo inā makemake ʻoe, hiki iā mākou ke hāʻawi i kahi laʻana iā ʻoe e hoʻāʻo.

Hoʻopaʻa ʻia kā mākou huahana huahana e Sichuan Metallurgical Institute a me Guangzhou Institute of Metal Research.Hiki i ka hui lōʻihi me lākou ke mālama i ka manawa hoʻāʻo nui no nā mea kūʻai aku.